FRLS-FR-HR-LDE

FRLS: This stands for “Fire Retardant Low Smoke.” FRLS cables are designed to limit the amount of smoke and toxic fumes released in the event of a fire. They are typically used in public buildings, hospitals, airports, and other areas where fire safety is a priority.

FR: This stands for “Fire Retardant.” FR cables are designed to resist the spread of fire and reduce the amount of smoke and toxic fumes that are released.

HR: This stands for “Heat Resistant.” HR cables are designed to withstand high temperatures and resist fire damage.

LDE: This stands for “Low Dielectric Loss.” LDE cables are designed to minimize the loss of energy as electrical signals travel through them.

- Fire retardancy: These cables are designed to resist the spread of fire and minimize the release of smoke and toxic fumes.

- Low smoke emission: The cables are made with materials that limit the amount of smoke released during a fire.

- Heat resistance: The cables can withstand high temperatures without getting damaged.

- Low dielectric loss: These cables have low energy loss as electrical signals travel through them, ensuring reliable signal transmission in high-frequency applications.

- Durability: The cables are designed to withstand harsh environments and are resistant to abrasion, chemicals, and moisture.

- High performance: The cables have excellent electrical and mechanical properties, ensuring reliable signal transmission over long distances.

- Compliance: FRLS-FR-HR-LDE cables meet international standards for fire safety and performance.

Power Plants, Data Center, Telecommunications, Infrastructure, Hospitals & Punbic Building, Transportation systems

- Copper conductors: Copper conductors are the most commonly used conductors in FRLS-FR-HR-LDE cables. They are highly conductive and have excellent resistance to corrosion and wear, making them ideal for a wide range of applications.

- Aluminum conductors: Aluminum conductors are used in some FRLS-FR-HR-LDE cables, especially for applications that require lightweight and flexible cables.

- Tinned copper conductors: Tinned copper conductors have a layer of tin coating over the copper, which enhances their resistance to corrosion and wear, making them ideal for use in harsh environments.

- Silver-plated copper conductors: Silver-plated copper conductors have a layer of silver coating over the copper, which enhances their conductivity and resistance to corrosion, making them ideal for use in high-frequency applications.

- Bare copper conductors: Bare copper conductors do not have any coating or plating and are used in some FRLS-FR-HR-LDE cables for applications that do not require enhanced resistance to corrosion or wear.

PVC (Polyvinyl Chloride), XLPE (Cross-Linked Polyethylene), LSZH (Low Smoke Zero Halogen), HFFR (Halogen-Free Flame-Retardant)

Explore Our Copper Products

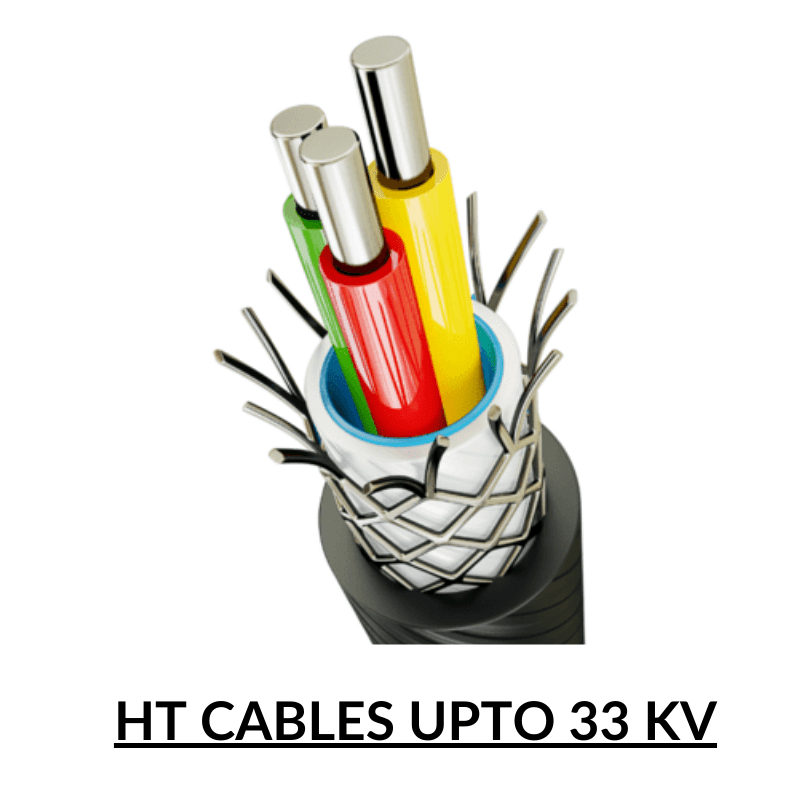

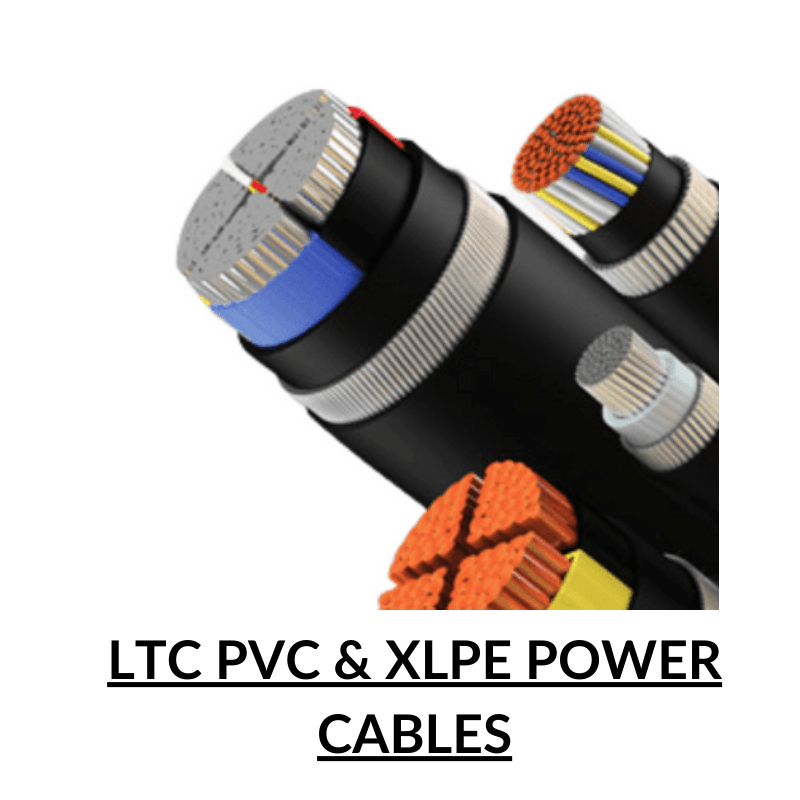

Explore Our Wire & Cables

FRLS-FR-HR-LDE

FRLS: This stands for “Fire Retardant Low Smoke.” FRLS cables are designed to limit the amount of smoke and toxic fumes released in the event of a fire. They are typically used in public buildings, hospitals, airports, and other areas where fire safety is a priority.

FR: This stands for “Fire Retardant.” FR cables are designed to resist the spread of fire and reduce the amount of smoke and toxic fumes that are released.

HR: This stands for “Heat Resistant.” HR cables are designed to withstand high temperatures and resist fire damage.

LDE: This stands for “Low Dielectric Loss.” LDE cables are designed to minimize the loss of energy as electrical signals travel through them.

Features

- Fire retardancy: These cables are designed to resist the spread of fire and minimize the release of smoke and toxic fumes.

- Low smoke emission: The cables are made with materials that limit the amount of smoke released during a fire.

- Heat resistance: The cables can withstand high temperatures without getting damaged.

- Low dielectric loss: These cables have low energy loss as electrical signals travel through them, ensuring reliable signal transmission in high-frequency applications.

- Durability: The cables are designed to withstand harsh environments and are resistant to abrasion, chemicals, and moisture.

- High performance: The cables have excellent electrical and mechanical properties, ensuring reliable signal transmission over long distances.

- Compliance: FRLS-FR-HR-LDE cables meet international standards for fire safety and performance.

Applications

Conductors

- Copper conductors: Copper conductors are the most commonly used conductors in FRLS-FR-HR-LDE cables. They are highly conductive and have excellent resistance to corrosion and wear, making them ideal for a wide range of applications.

- Aluminum conductors: Aluminum conductors are used in some FRLS-FR-HR-LDE cables, especially for applications that require lightweight and flexible cables.

- Tinned copper conductors: Tinned copper conductors have a layer of tin coating over the copper, which enhances their resistance to corrosion and wear, making them ideal for use in harsh environments.

- Silver-plated copper conductors: Silver-plated copper conductors have a layer of silver coating over the copper, which enhances their conductivity and resistance to corrosion, making them ideal for use in high-frequency applications.

- Bare copper conductors: Bare copper conductors do not have any coating or plating and are used in some FRLS-FR-HR-LDE cables for applications that do not require enhanced resistance to corrosion or wear.